UHMW-PE Roller

Ultra-high molecular weight polyethylene roller, UHMWPE roller has novel structure, reliable sealing and advanced material selection. The rollers and housings of the UHMWPE rollers are made of ultra-high molecular weight polyethylene (UHMWPE) with a molecular weight of 4.5 million to 12 million, which meets the American ASTM 4020 standard. Compared with traditional (existing) nylon, high density polyethylene (HDPE), phenolic phenolic, ceramic, iron roller, wear-resistant, lightweight, non-stick materials, no Damaged belt, seismic shock absorption energy and other advantages.

The UHMWPE roller is 7 times more wear-resistant than steel, 4 times that of nylon. It has anti-friction self-lubrication, impact resistance, noise and vibration elimination, anti-adhesion and anti-corrosion, resistant to aging, etc.

Properties:

1, Excellent abrasion resistance

The unique molecular structure of UHMW-PE products gives it a detached resistance to sliding friction. The wear resistance is higher than that of ordinary metal and plastic products, which is 6.6 times of carbon steel, 5.5 times of stainless steel, 27.3 times of brass, 17.9 times of phenolic resin, 5 times of nylon and 5 times of polytetrafluoroethylene.

2, The highest impact strength of any thermoplastic

In the existing engineering plastics, the impact toughness value of this product is high. Many materials will crack, break, break or surface fatigue in severe or repeated impact. This product is tested according to GB1843 standard for cantilever beam impact test without damage.

3, Superior chemical resistance, even to the most aggressive chemicals, including better chemical resistance than HDPE, P/U, steel and nylon.

This product can withstand the corrosion of strong chemicals, except for a slight corrosion of some strong acid at high temperature, in other lye, acid solution, it can be used in concentrated <80 °C concentration; at concentration <75 Among the %, the performance of nitric acid with a concentration of <20% is stable, and the performance of sea water and liquid detergent is also stable.

4, Very low friction coefficient

Due to the waxy nature of this product, the friction coefficient (196N, 2 hours) is only 0.219MN/m. Its own lubricity is very good, its sliding performance is better than oil-lubricated steel and brass; especially in harsh environment. In places with a lot of dust and sand, the dry lubrication performance of this product is more fully displayed, not only can it move freely, but also protects related work from being worn or strained.

5, Surface non-adhesive

This product has good surface non-adhesion due to its low friction coefficient and non-polarity. Existing materials generally scale in media with a pH of 9 or higher, and the product does not scale. This feature is of great significance for the use of thermal power stations for coal discharge ash systems.

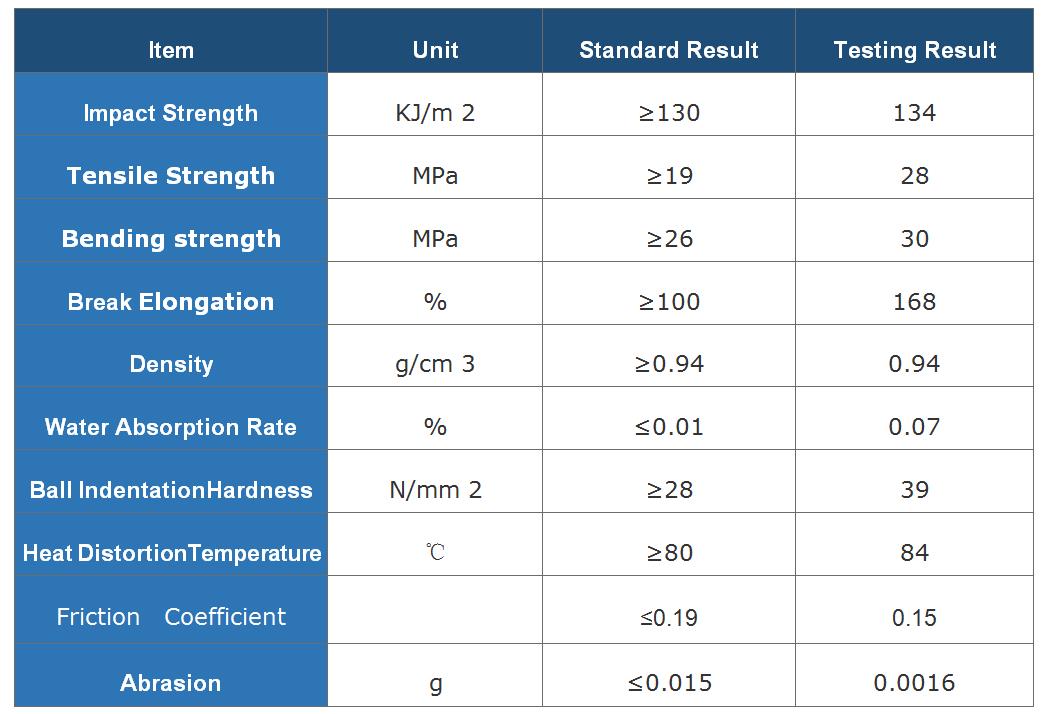

Parameters

UHMWPE Roller Application:

2. Food machinery: guard rail, star wheel, guide gear, roller, bearing lining, etc.;

3. Paper making machinery: suction box cover, deflector, wiper, hydrofoil;

4. Chemical industry: sealed filling board, packing material, vacuum mold box, pump parts, bearing bushing, gear, sealing joint surface;

5. Others: agricultural machinery, ship parts, electroplating industry, extremely low temperature mechanical parts.