Conveyor Impact Bed

Conveyor Impact Bed

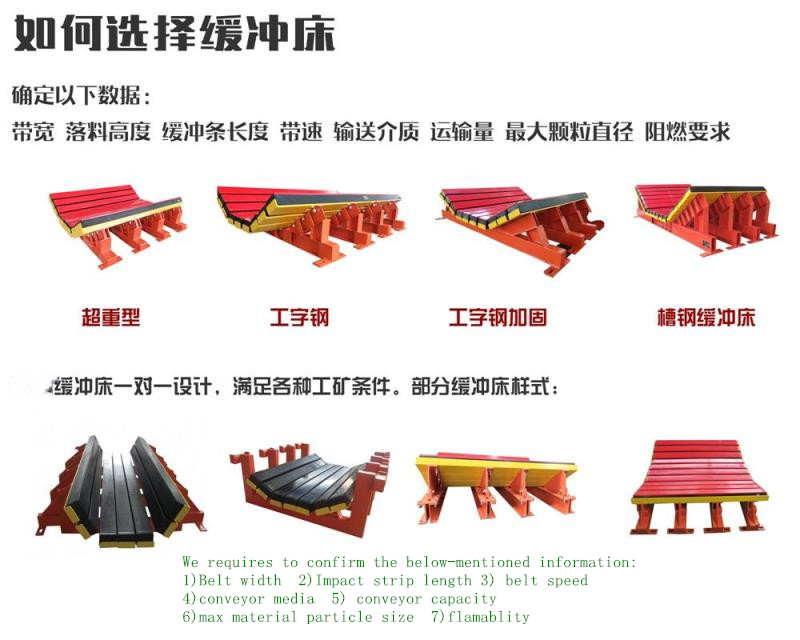

Impact bed is installed in the loading point of the conveyor belt to replace the traditional impact roller, It is designed to reduce shock and stress to conveyor belt caused by the falling materials, avoid abrasion and tear by sharp materials and prevent materials from falling and scattering

Features:

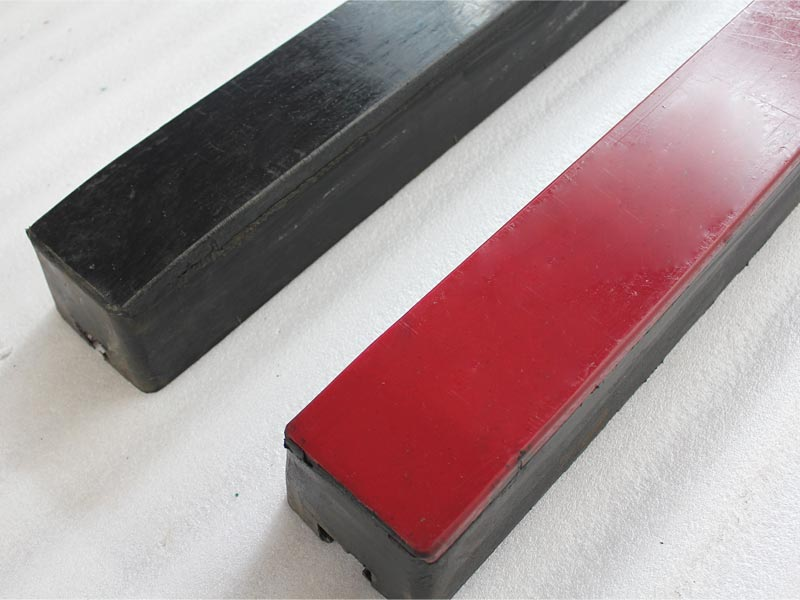

1. UHMWPE cap allows smooth movement of the conveyor belt.

2. Cushioning rubber absorbs impact energy.

3. Aluminum T-Slot is for fastening impact bars to the main support frame.

4. Hot vulcanization process makes sure the impact bar is integrated so well, that there is no possibility of separation.

5. We offer OEM service, can manufacture the different Impact Bed according to the customer's drawings or samples.

Application:

|

Applicable industries |

coal mines, power plants, steel mills, wharves, mines and cement plants |

|

Applicable materials |

Coal, stripped soil, ore, aggregate and cement...etc |

|

Applicable speed |

5.0m/s Max |

|

Suitable working conditions |

Reference rock particle size: 200mm

Max |

|

Ambient temperature |

-30-50ºC |

IMPACT BAR

|

Characteristics |

|

Coefficient of Friction 0.5 Service TemperatureRange -20° to 180°F (-29° to 82°C) |

|

Bar Construction |

|

Bearing Layer UHMW Polyethylene Absorption Layer 83A-Durometer Urethane T-Slot Aluminum Fasteners 1/2-inch diameter Bolts |

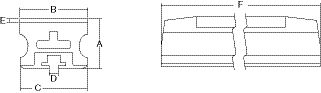

IMPACT BAR DIMENSIONS - in. (mm)

|

|

A |

B |

C |

D |

E |

F |

|

Urethane Bar |

3.0 (75) |

4.06 (103) |

4.0 (102) |

0.53 (13) |

0.5 (12) |

24 (610) |

|

48 (1220) |

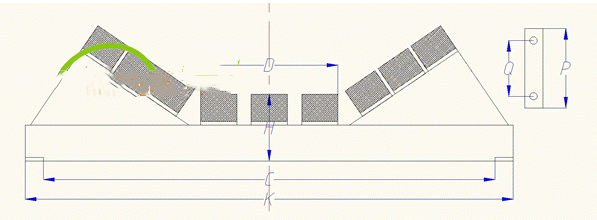

Installation size:

|

Belt Width (mm) |

Number of Bars (pc) |

Spacing on both side (mm) |

Bar Length |

Bar’s Number (Total ) |

Roller’s Width |

|||

|

Left |

Core |

Right |

Flank |

Middle |

||||

|

24’’(500-650) |

2 |

2 |

2 |

25 |

25 |

1200 |

6 |

250 |

|

30 (650-800) |

2 |

2 |

2 |

50 |

5 |

1200 |

6 |

315 |

|

36 (800-1000) |

2 |

2 |

3 |

25 |

25 |

1200 |

7 |

380 |

|

42 (1000-1200) |

3 |

3 |

3 |

55 |

20 |

1200 |

9 |

465 |

|

48 (1200-1400) |

3 |

4 |

3 |

45 |

7 |

1500 |

10 |

530 |

|

54 (1400-1600) |

3 |

4 |

3 |

25 |

25 |

1500 |

10 |

600 |

|

60 (1600-1800) |

4 |

5 |

4 |

25 |

10 |

1600 |

13 |

670 |

|

72 (1800-2000) |

4 |

5 |

4 |

20 |

25 |

1800 |

13 |

750 |

Notes: customized size specifications are available as client’s request

|

Belt Width (mm) |

H1 |

H2 |

K |

C |

D |

P |

Q |

|

24’’(500-650) |

185 |

200 |

36 (914) |

33 (838) |

240 |

220 |

160 |

|

30 (650-800) |

188 |

203 |

42 (1066) |

39 (991) |

270 |

220 |

160 |

|

36 (800-1000) |

216 |

331 |

48 (1219) |

45 (1143) |

370 |

220 |

160 |

|

42 (1000-1200) |

240 |

261 |

54 (1317) |

51 (1295) |

420 |

220 |

160 |

|

48 (1200-1400) |

251 |

266 |

60 (1529) |

57 (1448) |

500 |

220 |

160 |

|

54 (1400-1600) |

296 |

311 |

66 (1676) |

63 (1600) |

580 |

240 |

180 |

|

60 (1600-1800) |

315 |

320 |

72 (1829) |

69 (1752) |

710 |

240 |

180 |

|

72 (1800-2000) |

342 |

347 |

84 (2133) |

81 (2057) |

720 |

240 |

180 |

2. Metric dimensions indicate industry standards for metric belting, rather than a straight conversion.

* For Wide Base Impact Cradles, add 6 inches (150 mm) to Stringer Width and Mounting Centers dimensions.

** Replace any with the conveyor’s troughing angle (20°, 35,° 45°);

replace the final size with S for Standard Cradle or W for Wide Base Cradle.

3. Customized size specifications are available as client’s request