Steel Cord Conveyor Belt

Steel Cord Conveyor Belt

Product Property

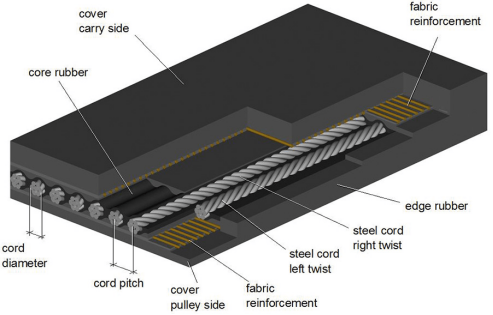

The tear-proof steel cord rubber conveyor belt for coal mining is used for the higher strength, less elongation galvanized steel cord, whose top and bottom surfaces are covered with strengthen transverse carcass and wearied aging-resistant rubber cover. When there is aculeate subject thrust, the belt can be protected and crack extending is prevented.

It can convey materials that require high strength, longevity and less elongation, long distance, good flexibility, good slot molding at the occasion, high speed, large loading, high strength in the field of coal mining, port, electricity, metallurgy, etc.

Application

The steel cord conveyor belt is commonly used in cement industry, coal mines, quarries, minings, electric power plants, metallurgic industry, ports and chemical industry, etc.

Advantages

Wire rope conveyor belts have many advantages such as high tensile strength, low elongation values, impact resistance and good plasticity. It is suitable for long-distance, large-capacity, high-speed transmission of large-scale, granular and powder materials.

More flexible, you need a smaller diameter drum.

The galvanized open steel cord and rubber have good adhesion and the adhesion between the steel cord and the rubber is very tight. The belt is impact resistant and has a long service life.

Using advanced manufacturing techniques, the wire ropes are evenly arranged and the tension is the same. Therefore, the belt can run well and is difficult to escape.

According to the customer's special requirements, longitudinal cutting and tearing are limited by tensioning one or two layers of wire rope.

Type

Conventional, Fire Resistance, Conventional Fire Resistance, Heat Resistance, Abrasion Resistance, Heat & Abrasion Resistance, Acid & Alkali & Oil Resistance, Cold Resistance, Ozone Resistance.

Standards

Strict implementation of international standards: GB/T, DIN, AS, SABS, RMA, BS, JS etc.

Technical Date for Steel Cord Conveyor Belt

|

Belt Strength |

Cord diameter |

Cord structure |

Pitch |

Tension |

Cover thick mm |

Weight |

Pulley |

Cord strength |

|

ST-630 |

3.0 |

6*7+1WS |

10 |

90 |

5*5 |

20.2 |

800 |

6.93 |

|

ST-800 |

3.5 |

6*7+1WS |

10 |

110 |

5*5 |

20.6 |

800 |

8.8 |

|

ST-1000 |

4.0 |

6*7+1WS |

12 |

140 |

6*6 |

24.7 |

800 |

13.2 |

|

ST-1250 |

4.5 |

6*7+1WS |

12 |

175 |

6*6 |

25.4 |

800 |

16.5 |

|

ST-1600 |

5.0 |

6*19+1WS |

12 |

225 |

6*6 |

26 |

1000 |

21.12 |

|

ST-2000 |

6.0 |

6*19+1WS |

12 |

285 |

8*6 |

30 |

1000 |

26.4 |

|

ST-2500 |

7.5 |

6*19W+1WS |

15 |

355 |

8*6 |

32.2 |

1250 |

41.25 |

|

ST-3150 |

8.1 |

6*19W+1WS |

15 |

450 |

8*8 |

35.7 |

1400 |

51.98 |

|

ST-4000 |

9.1 |

6*19W+1WS |

16 |

570 |

8*8 |

37.8 |

1600 |

74.8 |

|

ST-4500 |

9.7 |

6*19W+1WS |

16 |

645 |

8*8 |

38.7 |

1800 |

79.2 |

|

ST-5000 |

10.9 |

6*19W+1WS |

17 |

751 |

8.5*8.5 |

41.9 |

1800 |

93.5 |

|

ST-5400 |

11.3 |

6*19W+1WS |

17 |

760 |

9*9 |

43.9 |

2000 |

101 |

|

ST-6300 |

12.3 |

6*19W+1WS |

18 |

900 |

10*10 |

48.3 |

2000 |

124.74 |

Thickness of the cover, steel cord diameter and distance of steel cord can be designed according to per your requirement.

Rubber Cover Performance

|

Items |

|

Characteristics |

|

|

|

|

|

D |

H |

L |

|

Tension Strength |

Mpa≥ |

18.0 |

24.0 |

15.0 |

|

Elongation at break |

%≥ |

400 |

450 |

350 |

|

Abrasion |

mm3≤ |

100 |

120 |

200 |

Notes: Width 1200 ST1600 8.0+6.0 H

Width 1200 is the belt width. ST1600 means the steel cord type. 8.0+6.0 is the top and bottom thickness. H means the rubber cover quality standard.